-40%

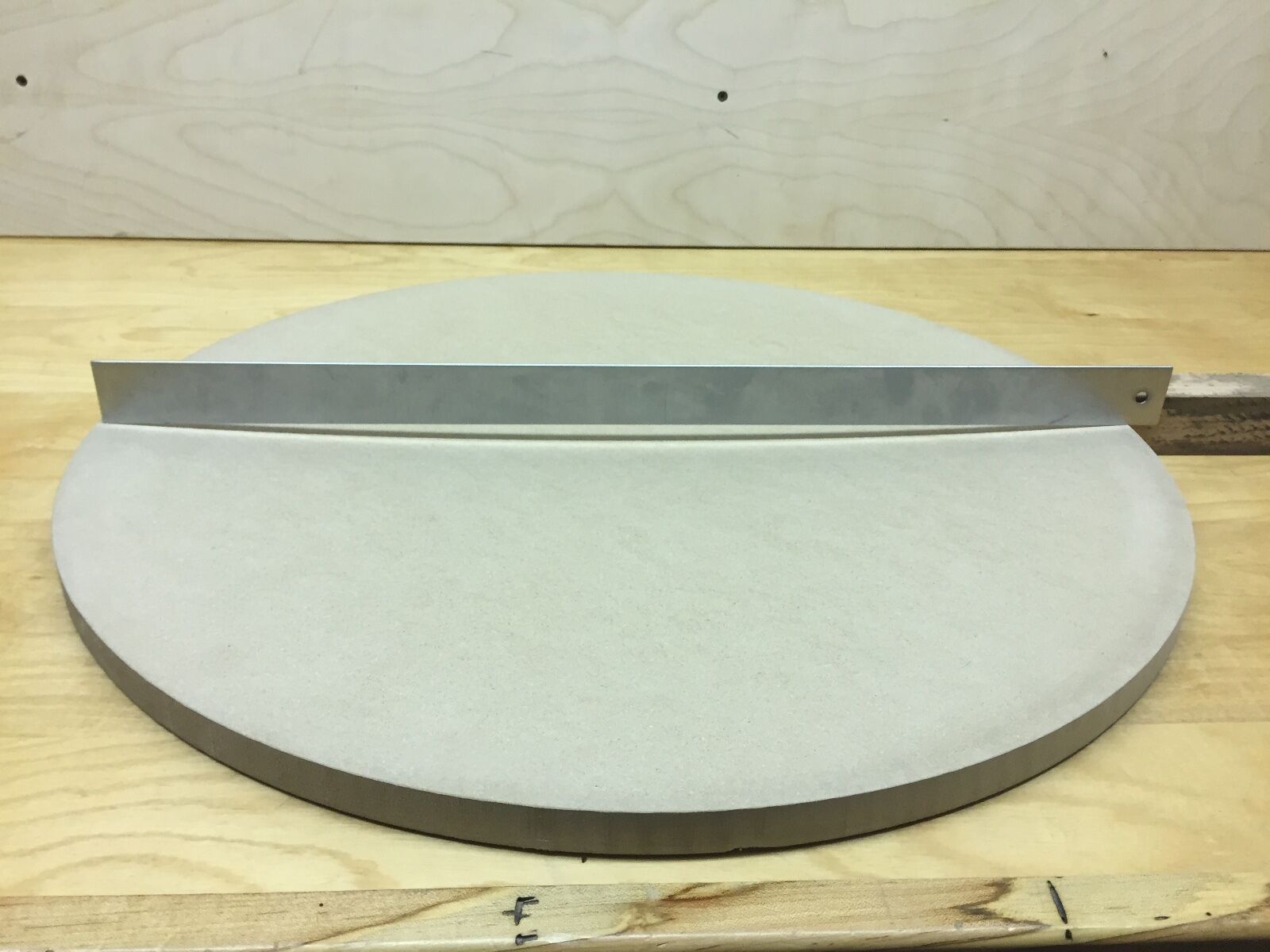

Luthier's Radiused Dish Form - Custom Radius (12' or Greater)

$ 34.32

- Description

- Size Guide

Description

Luthier's Radiused FormsAny radius available

upon request

The Indiana School of Lutherie Bookstore

CNC Radius Dish Hollow Forms.

They are made from 3/4" Solid MDF and are made to very strict tolerances by cutting

concentric circles o

n a CNC machine. All sales from our bookstore go toward the further development of our non profit Lutherie School. Please keep in mind, when you purchase from our bookstore, you are helping to further the development of lutherie and help those in their quest to become better Luthiers!

We appreciate your support! 10'r and smaller also available on a separate

listing.

How to Care for your radiused dish

Please follow these instructions to ensure your form remains accurate

When you receive your form, allow your dish to acclimate (on a rack that allows air on all sides) in a dry, climate controlled

environment

for 48-72. hrs.

Immediately following

we recommend gluing your form down to a solid backing base such as 3/4" MDF. You want to use something stable, and MDF seems to do an excellent job. Some luthiers even use a double deck as a backing board for extra stability. If you prefer to use plywood, one should use a higher grade, Baltic birch furniture grade ply with multiple ply (11-13) ply. You should

NOT

use your average plywood available at local Lowes or Home depot. MDF however, is readily available at these stores and would be a much better choice.

After a reasonable glue cure time (at least 24-48 hrs for titebond), seal your dish. Do not wait to long to get your dish sealed, using a couple thin coats of sanding sealer such as Zinsser seal coat

(de-waxed is important)

Then,

lightly sand

before applying some type of durable finish, such as polyurethane, that will stand up to adhesives and solvents. I would recommend keeping your coats light to prevent any sagging but enought coats to protect your dish (a minimum of 2). I would also

recommend sealing all sides, top, and bottom of your completed jig, including base decks.